The motion prediction of offshore vessel and crane load in relation to the wind energy turbine is of high importance for installation and maintenance processes regarding safety and financial aspects.

On the one hand, the technicians’ safety at sea during different offshore operations (transfer from vessel to wind energy turbine, installation of components with a crane) is of highest priority, as well for the executing company as for the energy providers. On the other hand, the coast for installation and maintenance can exceed 25 % of the LCOE (levelized cost of energy) of a bottom-fixed wind energy turbine. There is a direct link between technicians’ safety and the cost of the operation, as an exceedance of the operation’s threshold values (e.g. wave height) lead to standstill of the chartered work vessel and thus to high costs. Therefore, the minimization of these standstills is an important aspect in reducing the cost of offshore operations, leading to a lower LCOE and lower energy prices.

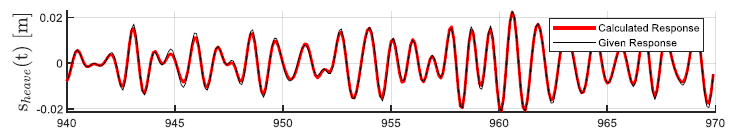

To reach this aim, a detailed knowledge of the motion of the different components and vessels is necessary. To generate this knowledge, a real-time capable model is developed in subproject A06, being applicable during the planning stage as well as on the vessel for a real-time prediction of the motion in combination with a wave radar.

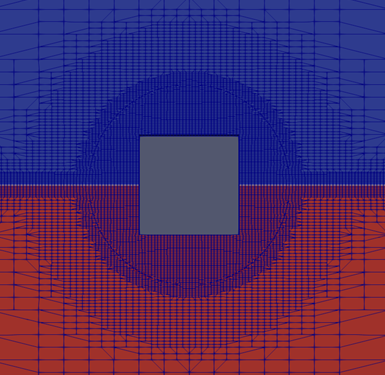

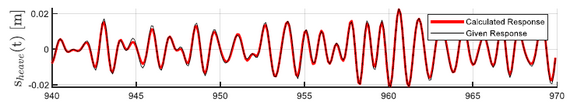

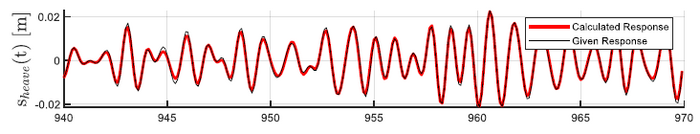

The model is based on the equation of motion of floating structures in waves. Multiple hydrodynamic parameters like hydrodynamic mass, damping and wave force are needed to solve this linear equation. Many of these parameters can be determined using conventional models basing on potential theory. But as these models neglect viscosity, the damping terms in the equation of motion are underestimated, leading to wrong motion prediction. Thus, the first focus of this subproject is to parametrize the hydrodynamic parameters using Forced Oscillation tests. Initially, these tests will be done in the laboratory, to use these experimental results in the verification and validation of a numerical model, which will then be used to extend the insights from the model tests. The numerical model has some advantages in visualizing the nearfield hydrodynamics, which can only be obtained in physical model tests via elaborate PIV-tests. These PIV-tests will also be used in the subproject A06 focusing on the creation on benchmark datasets and extending the model tests’ scope.

These experimental and numerical investigations are focusing on the parametrization of the hydrodynamic coefficients and the influence of viscous effects. A special emphasis is laid on the influence of structural attachments like bilge keels or heave plates, which have the purpose to decrease the motion response in waves, thus leading to higher safety and less standstill and cost. In this matter, synergy effects with other subprojects will be investigated, e.g. with subproject A04 with the topic of scour and scour protection.

The second focus of this subproject is the creation of a real-time model based on the previously determined hydrodynamic parameters. The aim is a model with more than 6 dimensions, considering crane load motion and incorporating non-linear effects. As the equation of motion depicts a linear system, non-linearities must be included via additional models, which poses another challenge regarding the real-time capabilities of the model.

Finally, the real-time model should be coupled to the digital twin to enable its use in the substructure design in subproject B01. Using the model, unfavorable designs leading to high risk, standstill and costs during installation and maintenance processes can be neglected and the logistically optimal substructure can be identified.

Publications

-

Dezember 2021: Experimental investigation of offshore crane load during installation of a wind turbine jacket substructure in regular waves

Aliyar, S., Meyer, J., Venkatachalam, S., Hildebrandt, A. (2021)

Experimental investigation of offshore crane load during installation of a wind turbine jacket substructure in regular waves

Ocean Engineering, 241 -

October 2022: A Comparison of Different Numerical Methods to Simulate Forced Roll Oscillations of Floating Structures in Grid-Based Schemes

Meyer, Jannik; Neufeldt, Henrik; Hildebrandt, Arndt

A Comparison of Different Numerical Methods to Simulate Forced Roll Oscillations of Floating Structures in Grid-Based Schemes

Proceedings of the ASME 2022 41st International Conference on Ocean, Offshore and Arctic Engineering. Volume 7: CFD and FSI. Hamburg, Germany. June 5–10, 2022. V007T08A054. ASME

Subproject Management

30167 Hannover

Staff

30167 Hannover